To understand the opportunities a heat pipe can bring in LED luminaires, you have to look first in the basic principles of lighting and optics.

The smaller the light source (LES – Light Emitting Surface), the easier a beam shape and beam pattern can be created from that light source.

So for lighting applications where light distribution is a must, you want to create a light source as small as possible in order to have a perfect beam control.

In LED lighting more complex beam shapes are created through a TIR or Total Internal Reflection lens. But there is of course a drawback on that – small light sources means also a high concentration of heat on a small surface that needs to be cooled, and that’s where heat pipes fit in.

Nowadays Highbay LED luminary power reaches +600W with extremely high thermal power, where Copper and Aluminum is both not capable to handle, heat pipe is an easy and price friendly alternative to transport the heat away from the light source towards an area where the convection and radiation can be realized.

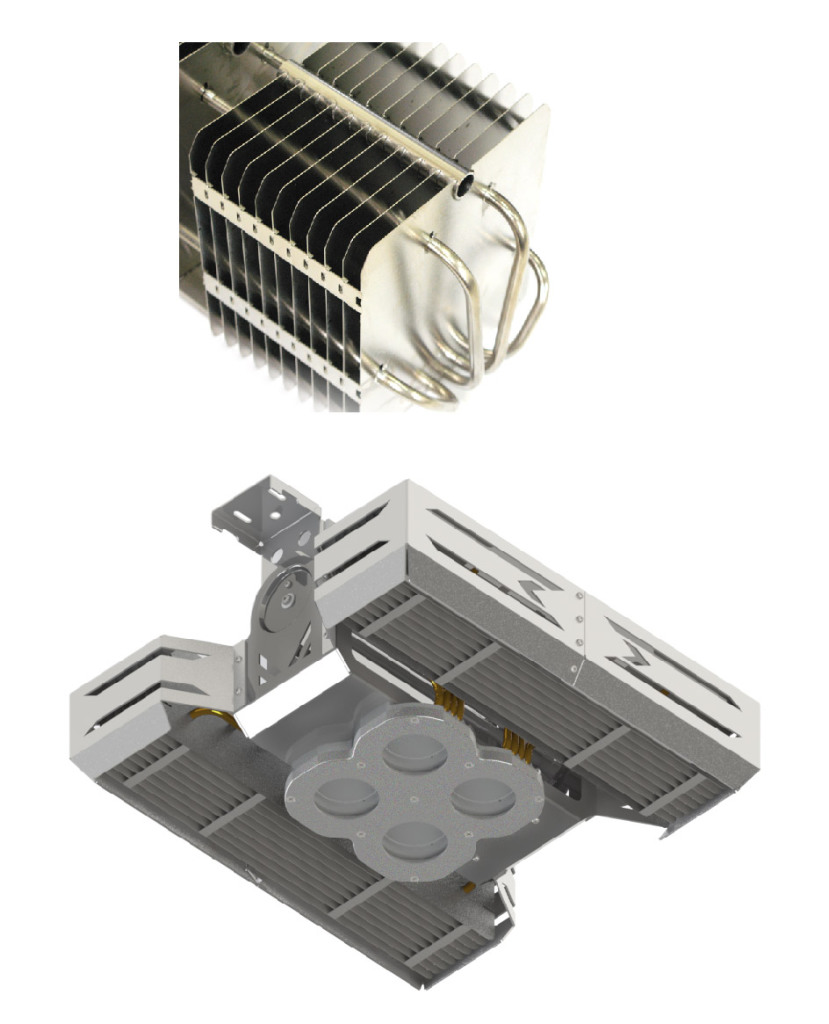

To secure product life and reliability, light weight and high performance natural convection cooler with heat pipes and stacked fins is adapted.

Challenge:

- Passive cooling solution for extremely high heat flux

- 350~450 watts of heat flux from emitters and the air temperature could be up to 35 °C

- Light weight and efficient thermal design

- Ingress protection rating +IP65

Solution:

- High performance heat pipe and stacked fin to dissipate thermal power by natural convection

- Optimal air flow path and thermal performance for the application

繁體中文

繁體中文  English

English