Customized heat sink development and the manufacturing process

There are options to heat sink and cooler’s material and manufacturing process. Copper, aluminum, graphite and ceramic are commonly used, among them, aluminum & aluminum alloy is the most popular one because of its light weight (density = 2.7 g/cm³), good heat conduction (K=90~195 W/m-K), and easy to fabricate. The performance of the heat sink not only depends on material’s thermal conductivity, but also the heat exchange fin settings, such as fin thickness, height and spacing….etc. Comparing with other materials, aluminum has various processes which are matured enough to make the design highly flexible to fulfill either natural convection or forced convection requirement. Available heat sink & cooler design and process :

Aluminum extrusion

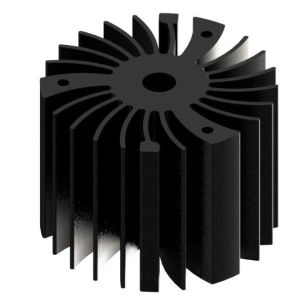

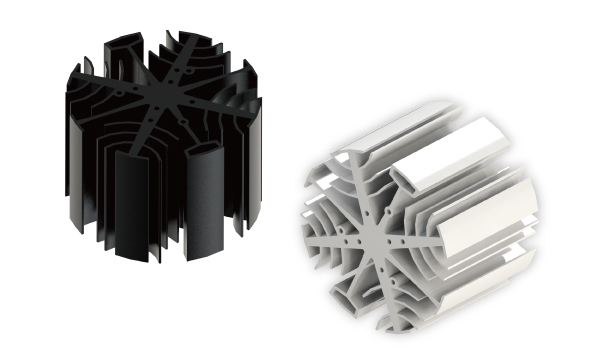

The following photograph shows examples of extrusion heat sinks. To develop an extrusion heat sink, firstly is to determine the cross-section profile, fin area, thickness and spacing are crucial heat exchange efficiency. Post processing includes length cutting, drilling, tapping), CNC machining of specific features or removal of materials, surface treatment… etc., is then adapted to complete heat sinks.

The aluminum extrusion mold cost and process is relatively low and simple, so it’s the most common fabrication process to mechanical parts and heat sink.

The material is aluminum alloy A6063 or A6061 with thermal conductivity range 150~195 W/m-K.

The sectional profile is limited by strength of the finest features on production mold. Normally fins’s spacing/thickness ratio, L/t = 20 is about the production upper limits, with higher L/t, the greater pressure to the mold with higher risk to damage the tool; If L/t <15, the mold’s stress during production is low so the yield is smoother and more stable. Therefore, development process requires close communication with the manufacturer to ensure good manufacturing process in production.

Forging

Forging

This forming technique is to place a pre-heated or un-preheated metal in a specific mold, and apply a strong forging pressure to deform the work piece. Copper and aluminum forging is common process to fabricate heat sinks. Compared with die casting, the forged parts are stronger with higher thermal conductivity, Fin area can be increased with higher heat exchange rate in a limited space. However, the cost of the forging die is high, and the plastic flow of the material in the manufacturing process occasionally causes uneven material distribution, which must be considered during development.

Stacked fin – progressive die stamping

The stacked fin (or so call zipper fin) are made by progressive stamping process. The designs of fin is highly flexible, also very suitable to adapt with heat pipes or vapor chambers for high power, forced convection or low thermal resistance projects. Common materials are aluminum (A1050) or copper (C1100). There is wide options of stacked fin thickness, determined by thickness of standard sheet metal, common thickness is 0.2, 0.3, 0.4 and 0.8mm. Fin pitch, fin quantity, length and fin shape can be adjusted to demand.

繁體中文

繁體中文  English

English