Heat pipe is a heat transfer device that combines the principles of both thermal conductivity and phase transition to efficiently manage the transfer of heat between two solid interfaces. At the evaporation area, working fluid turns into vapor by absorbing heat from the source, then by the effect of pressure difference the vapor travels along the pipe to other end in contact with cold surface or fins, and condense back to the liquid after heat exchanging. After the condensation, the liquid flows back to the evaporation area by papillary and gravity force, thus as one cycle.

Due to the very high heat transfer efficiency of phase changing mechanism at both evaporation and condensation ends, heat pipes (also vapor chamber or loop thermosyphon) can transfer much more heat than any other solid materials, the equivalent thermal conductivity of heat pipe can be 8,000~15,000 W/m-K, which is 40~80 times of Aluminum.

The standard heat pipe dimeters is D3, 4, 5, 6, 8 and 10mm, length, flattening thickness and bends can be customized to fulfill the mechanical request from customers. Table 1 below shows the minimal suggested bending radius for different diameter heat pipes, Table 2 lists the width of flattened heat pipe for designer’s reference. The wick structure inside is an important feature of heat pipes, which offers capillary force to pull the liquid back to the evaporation when working anti-gravity. Our heat pipe includes Groove, Mesh and Sinter type, each has the advantages and trade-offs over thermal performance and manufacturing, so you are welcome to contact us before selection.

Groove Heat Pipe

The groove wick is formed on the tube itself, it’s a cost effective solution with very stable thermal performance.

Sinter Heat Pipe

The porous wicks used in heat pipes are manufactured using copper powder sintered at 850~1000°C. These wicks’ porosity and pore size distribution influences the liquid phase flow significantly, therefore the quality and process stability is crucial. When compared with groove or mesh types, the advantage of these sintered wicks appears the controllability of porosity and pore size for heat pipe performance optimization.

Mesh Heat Pipe

Mesh heat pipe is composed of a smooth wall copper tube and copper mesh installed along the pipe internally. The copper mesh is designed to contact to the pipe, offers capillary force to pull the liquid back.

Heat pipe Table 1

| D Heat pipe diameter (mm) |

R Suggested Min. Bending Radius (mm) |

| 3 | 7.5 |

| 4 | 10 |

| 5 | 12.5 |

| 6 | 15 |

| 8 | 20 |

| 10 | 25 |

Heat pipe Table 2

| Heat pipe diameter (mm) |

Flatten thickness (mm) |

Width (Tolerance ± 0.15mm) |

| 2 | 1.5 | 2.4 |

3 |

2.5 | 3.4 |

|---|---|---|

| 2.0 | 3.7 | |

| 1.8 | 3.8 | |

| 1.2 | 4.1 | |

4 |

2.5 | 5.0 |

| 2.0 | 5.3 | |

| 1.5 | 5.6 | |

| 1.2 | 5.7 | |

5 |

3.0 | 6.3 |

| 2.5 | 6.6 | |

| 2.0 | 6.9 | |

| 1.5 | 7.2 | |

6 |

4.0 | 7.3 |

| 3.5 | 7.7 | |

| 3.0 | 8.0 | |

| 2.0 | 8.5 | |

8 |

5.0 | 10.0 |

| 4.0 | 10.6 | |

| 3.0 | 11.1 | |

| 2.0 | 11.9 | |

10 |

9.0 | 10.8 |

| 7.0 | 12.1 | |

| 5.0 | 13.2 | |

| 3.0 | 14.2 |

Heat pipe working fluid selection

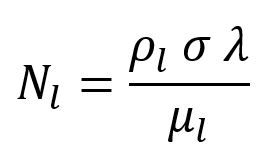

There are options to heat pipe working fluid, such as water, methanol, ammonia ….etc. a Merit number introduced by Chi in 1976 is used to evaluated the working fluid of heat pipe in different working temperature range.

ρl Liquid density

σ Surface tension

λ Latent heat

μl Liquid viscosity

In this Merit number calculation, working fluid’s density, latent heat and surface tension act as numerator, which means that the higher the value, the more suitable to be selected as heat pipe working fluid.

The denominator is fluid’s viscosity, the higher the number, the more unfavorable it is as a heat transfer medium.

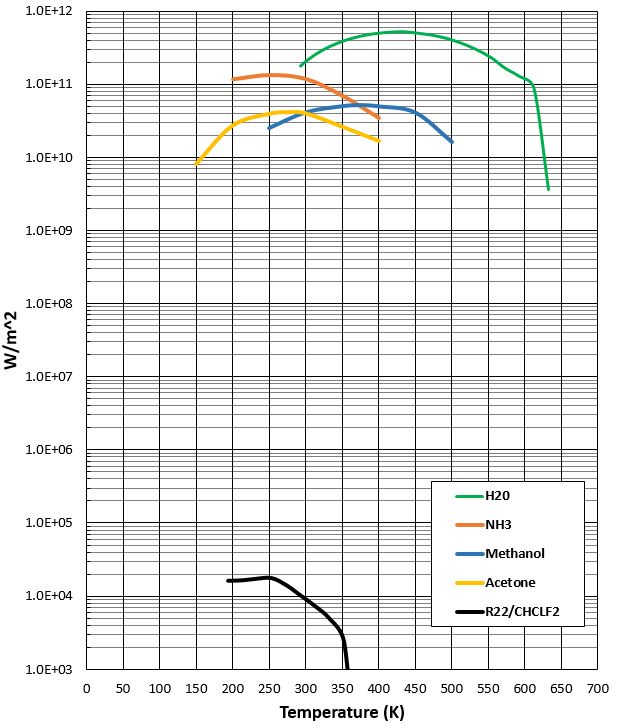

The following figure uses water (H2O), methanol (Methanol), acetone (Acetone), ammonia (Ammonia, NH3) and R22 refrigerant as examples to compare the fluids at different temperatures as the evaluation parameters of heat pipe working fluid. It shows H2O’s merit number is at least 10 times higher to other fluids, therefore it is the best choice for heat pipe working fluid among a wide operation temperature range.

![]() Filedownload Error: file 'http://coolinghouse.com/wp-content/uploads/2020/01/Cooling-House-heat-pipe-white-paper-V21.pdf' does not exist!

Filedownload Error: file 'http://coolinghouse.com/wp-content/uploads/2020/01/Cooling-House-heat-pipe-white-paper-V21.pdf' does not exist!

繁體中文

繁體中文  English

English