Soldering process is the traditional fabrication process for thermal modules and coolers. Soldering paste is applied or screen-printed to heat pipes, base plates and fins, with soldering process fixture the pre-assembly is transported into reflow furnace. In the over solder paste is melted and flows to fill up gap of each parts. Afterwards, heat pipes, base plates, fins and other mechanical components are soldered together with high heat transfer capability.

If component of fins is made of aluminum or steel, we need to apply Nickle plating to the parts firstly to be applicable to solder paste. However, the surface treatment to Aluminum and reflow oven process discharge certain pollutants. In recent years, the environmental protection regulations and restrictions have increased, thus increases the cost of soldering process. Therefore, the development of the soldering-free process has been carried out to reduce environmental impacts, metal riveting and stamping process, which discharge very limited pollutants, is used to for thermal modules and combine parts with no difference thermal performance.

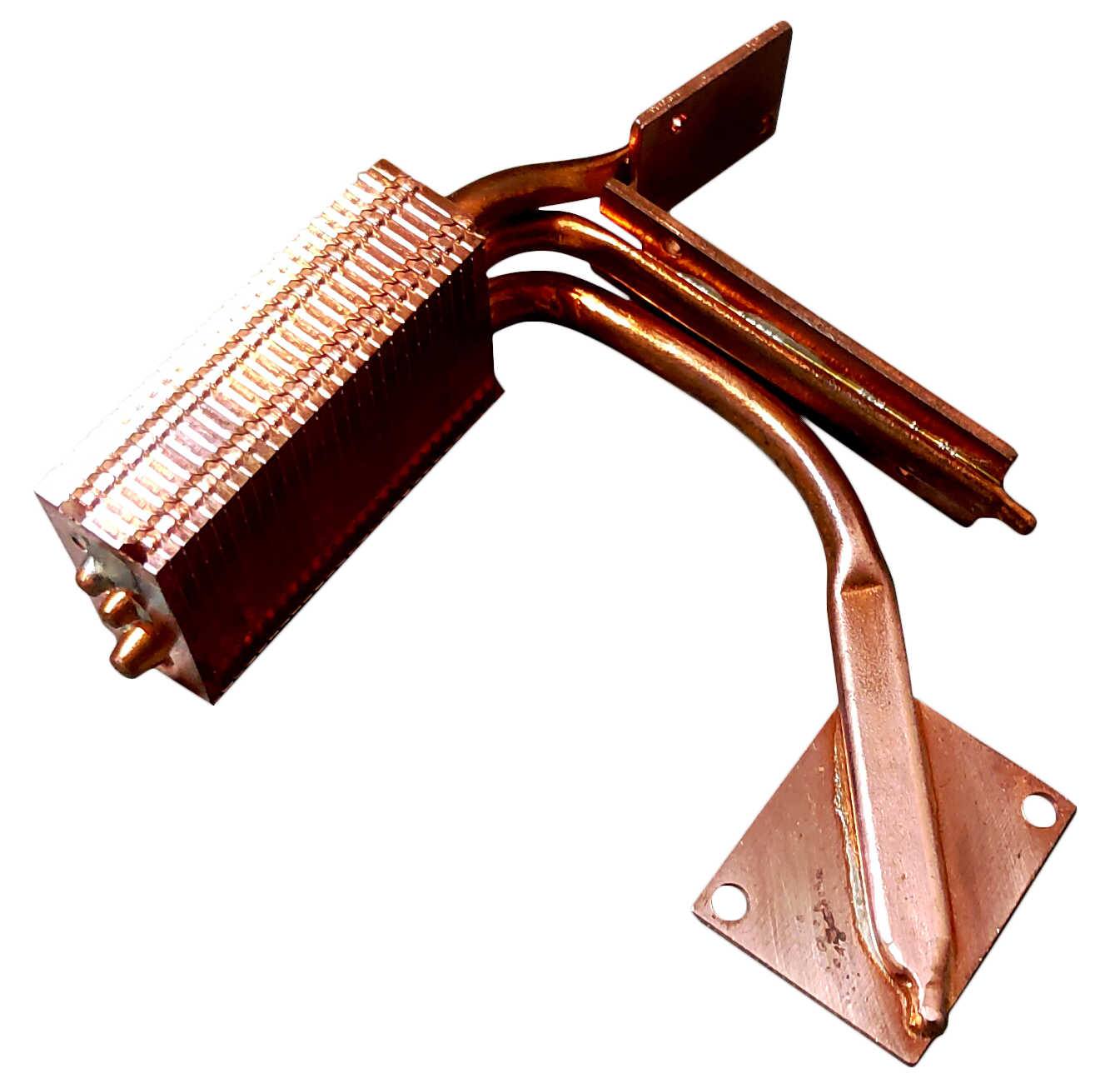

▲Soldering heat pipes sample

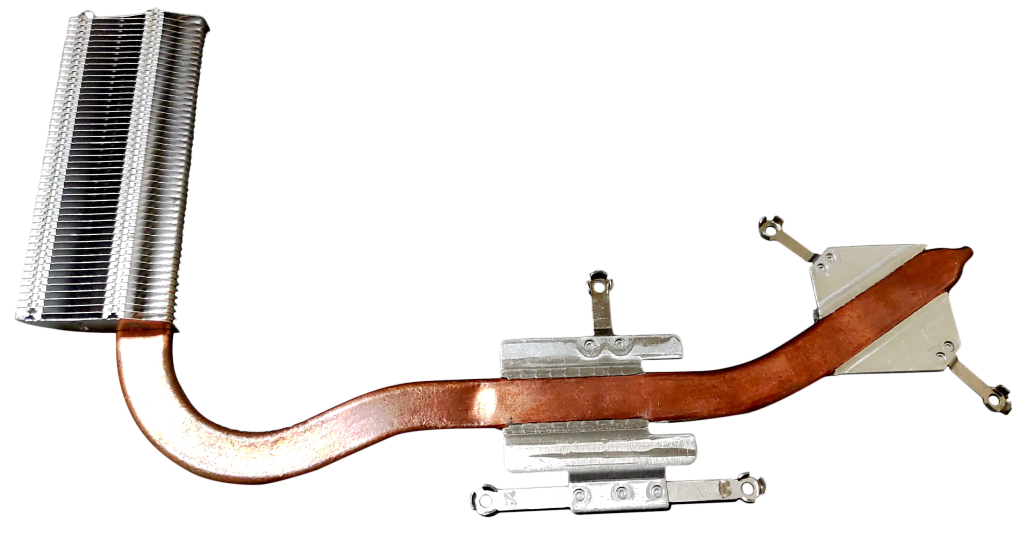

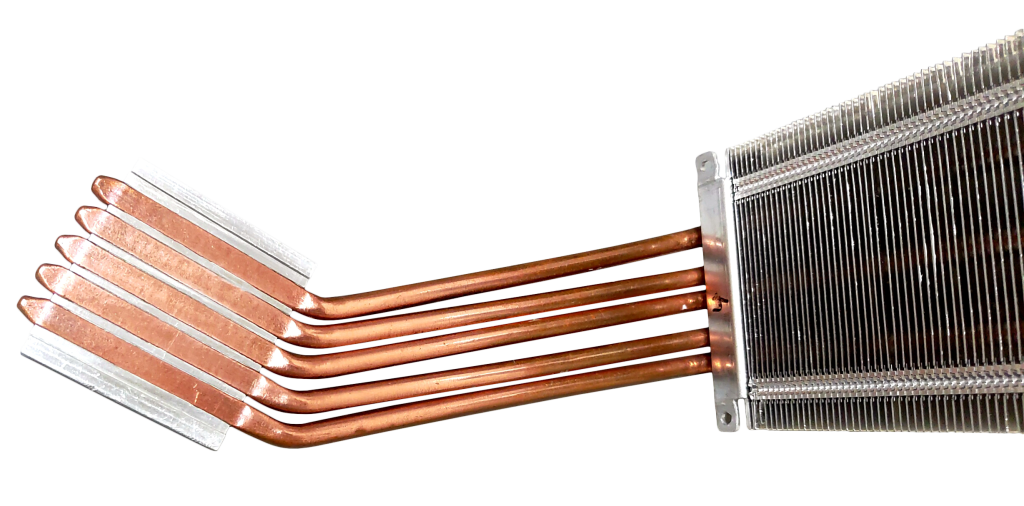

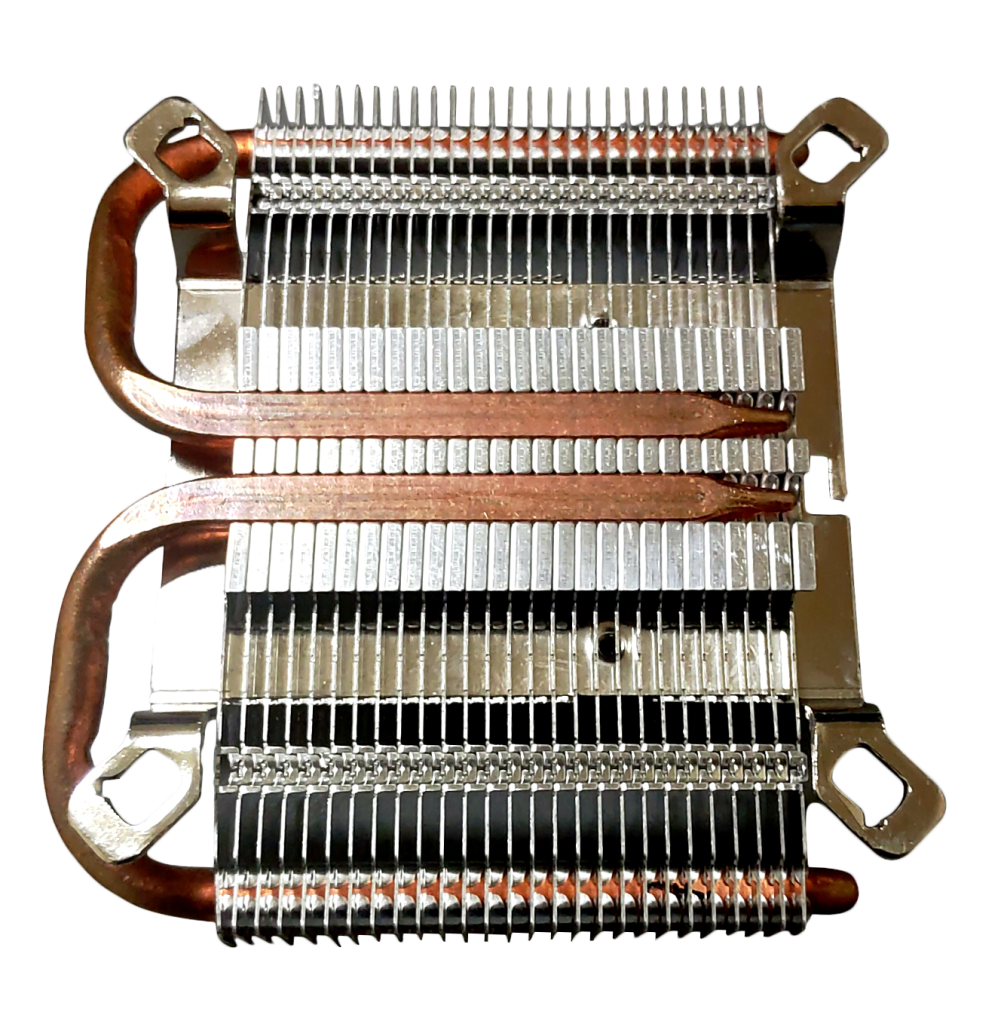

▲Soldering free thermal module

繁體中文

繁體中文  English

English