錫焊製程是散熱模組傳統的製造方式,組裝時用點膠機或是網印到熱導管、底板、鰭片上,利用組裝治具夾持,送入迴焊爐內,錫膏或焊料熔融之後理想上會流到各個零件間隙,出爐之後將熱導管、底板、鰭片和其他機構件結合在一起,達到高熱傳導與結合機構件之目的。

組件是鋁材或鋼材時,熔融錫膏不會濕潤沾黏,需先行鍍鎳或化鎳表面處理。然而表面處理和錫爐製程會排放固定的汙染物質,近年環境保護的規範與限制逐步提高,散熱器錫膏銲接製程的成本大幅提高,故有無錫焊製程之開發,透過相對較環保的金屬鉚接和鍛打製程,取代化學結合製程。

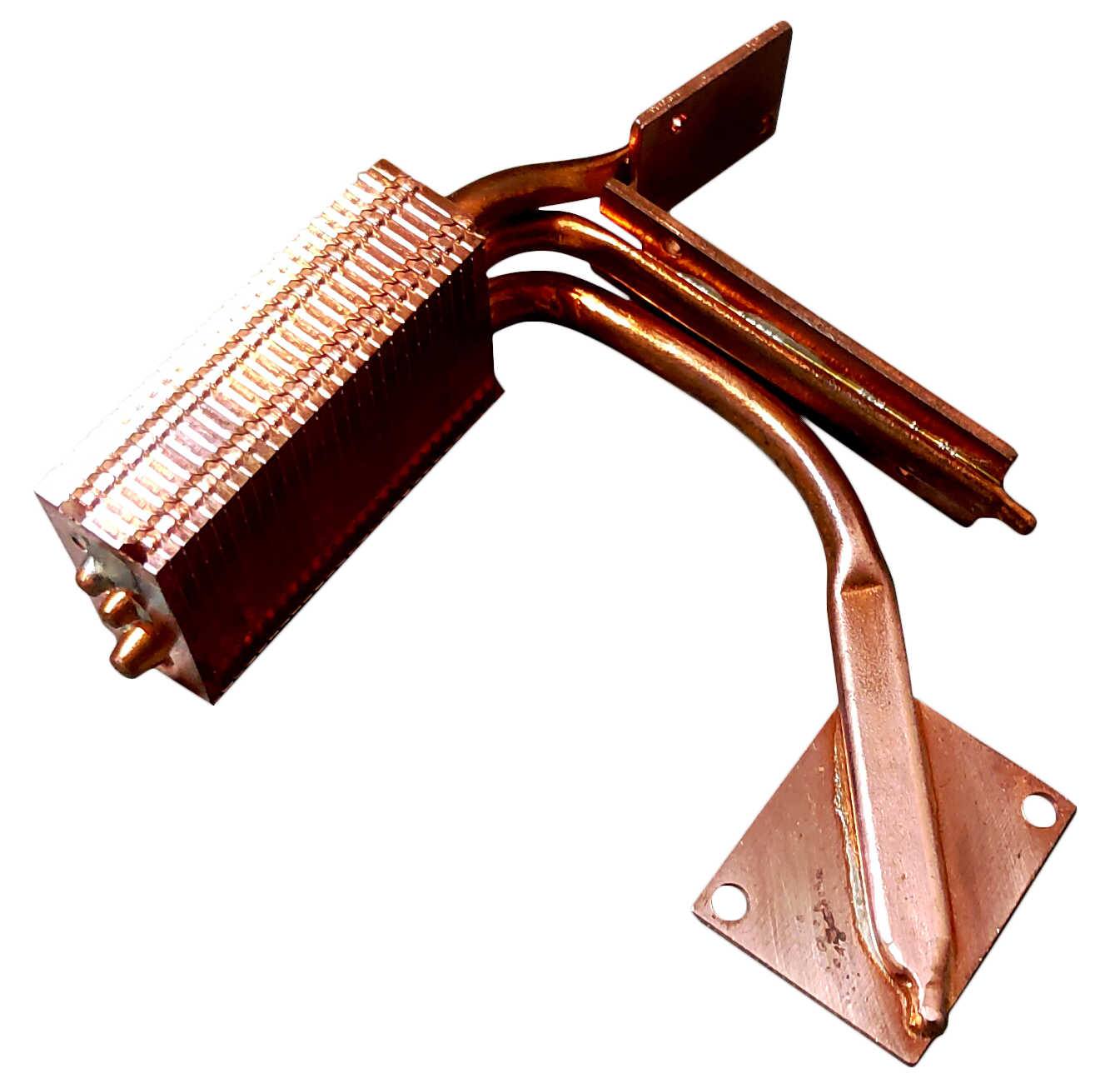

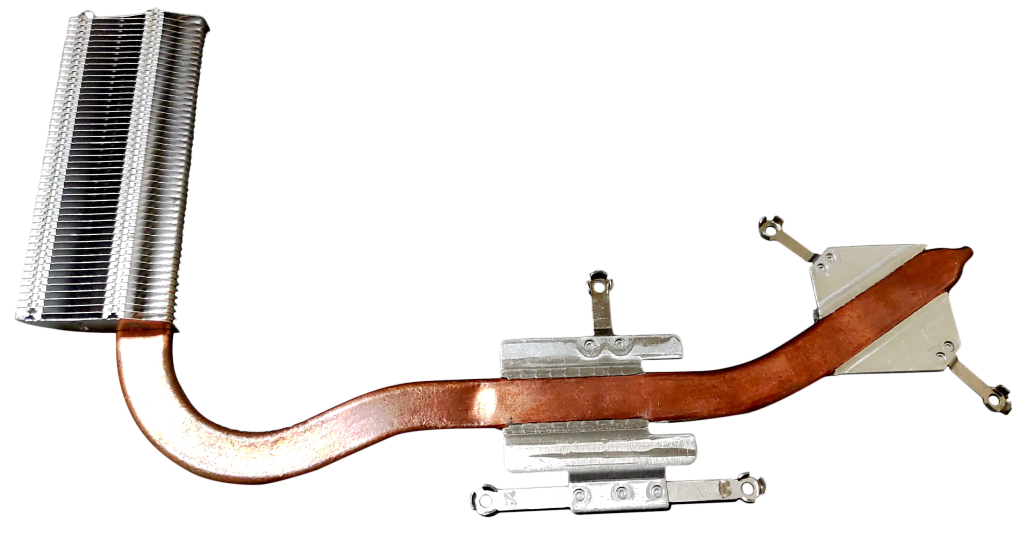

▲無錫焊散熱模組樣品

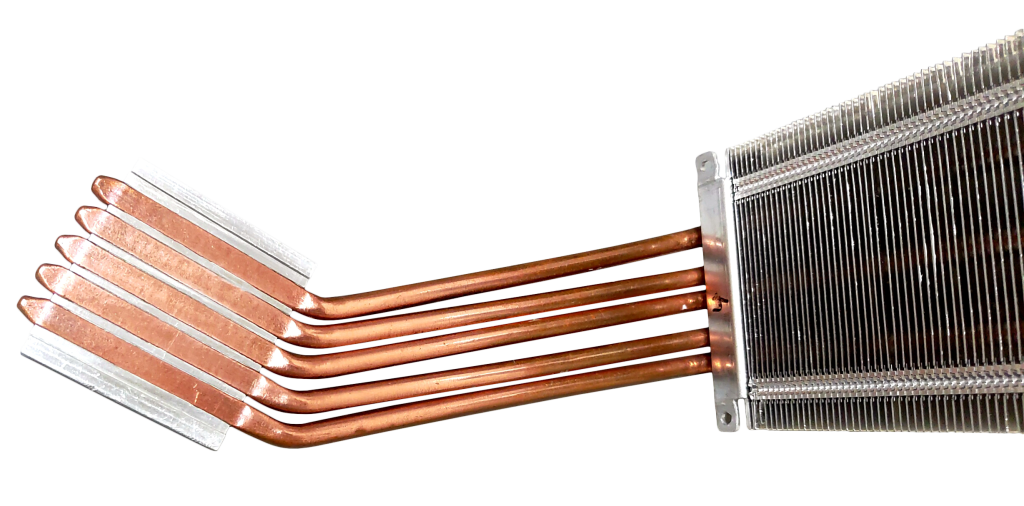

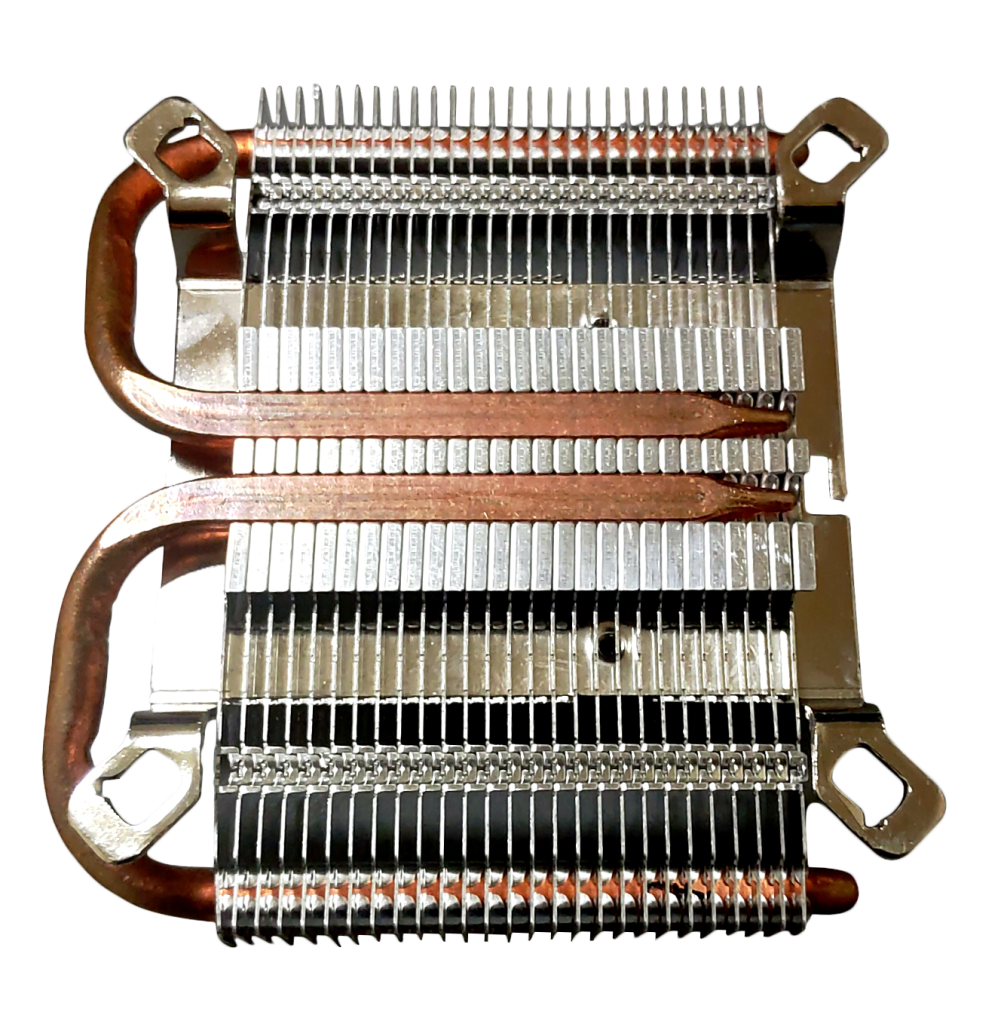

▲無錫焊製程實樣

繁體中文

繁體中文  English

English