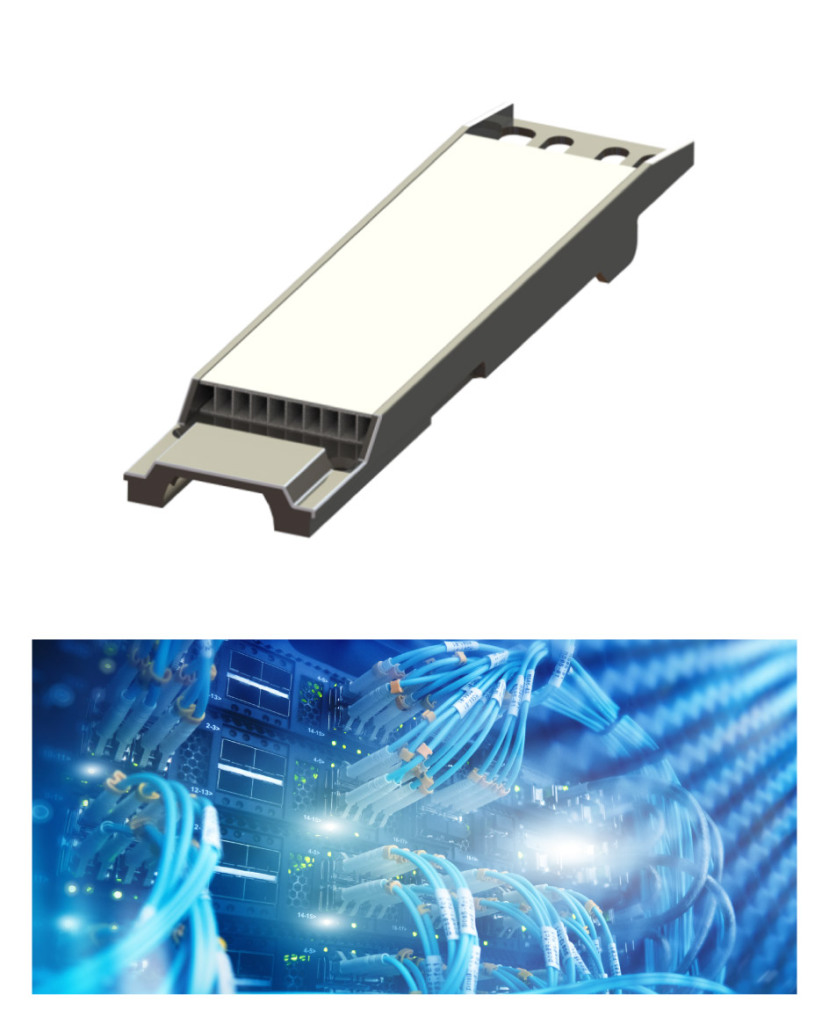

Fiber optical transceiver is one of the key components of the fiber optic communication systems. It is composed of massage receiver and transmitter of the communication process. The fiber optical transceiver modules convert electrical signal and optical signal to each other to exchange information, meanwhile dissipate heat flux. With the increase of transfer speed, thermal performance of conventional Zinc alloy die-casting housing is challenged and gradually unable to handle the increasing power. We propose High-K Aluminum alloy die-casting (Thermal conductivity =150W/m-K) and stacked fins for next generation transceiver module’s housing, which improves thermal conductivity and create significantly more fin area within the limited space, weight reduction to fiber optical transceiver is another plus (Aluminum alloy density V.S. Zinc alloy density, 2.7 V.S. 6.6 g/cm³).

Challenge:

- High heat flux within a limited space

- 5~30 watts of dynamic heat flux

- Light weight and durable to mating and plugging

- Superior active cooling performance to handle high power density

Solution:

- High-K Aluminum alloy die casting and stacked fin design

- Stainless steel top cover for the mating and plugging process

- Optimized active cooling performance to reduce needed fans power consumption of fiber optic communication system

繁體中文

繁體中文  English

English