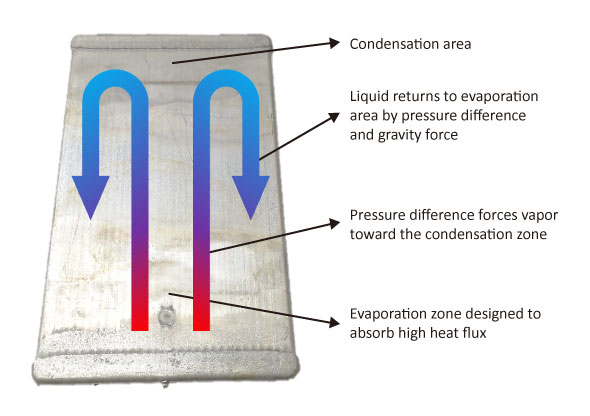

The heat spreader is a closed-loop 2 phase flow device with an enormous heat spreading capacity.

Below the picture shows it’s working principle, this phase change heat transfer device can move tremendous thermal power away from the heat source. With microchannels inside, the heat exchange area is maximized and the working fluid flow is regulated, working fluid boils and generates a pressure difference, which forces the vapor and heat to the condensation zone, gas is then condensed and returned to the evaporation area as a completed cycle.

The Aluminum heat spreader is sealed by automobile industrial process, reliable, and predictable in its behavior, mostly it functions with gravity, with customized design our solution functions as well horizontally.

Advantages over traditional heat pipes

- Flat form factor offers tremendous more contact surface

- Micro channels structure for better heat exchange efficiency and mechanical strength

- Extremely high Q-max

- Suitable for display and EV battery pack cooling solution

| Width (mm) |

Thickness (mm) |

Length (mm) |

|

|

|---|---|---|---|---|

| CH-HSP1 | 41 | 5 | 100~1,800 | |

| CH-HSP2 | 67 | 5 | 100~1,800 | |

| CH-HSP3 | 66.5 | 2.5 | 100~1,800 | |

| CH-HSP4 | 90 | 5 | 100~1,800 | |

| CH-HSP5 | 125 | 5.5 | 100~1,800 |

![]() Filedownload Error: file 'http://coolinghouse.com/wp-content/uploads/2020/01/Cooling-House-Al-heat-spreader-white-paper-V11.pdf' does not exist!

Filedownload Error: file 'http://coolinghouse.com/wp-content/uploads/2020/01/Cooling-House-Al-heat-spreader-white-paper-V11.pdf' does not exist!

繁體中文

繁體中文  English

English